- AC Current Sensing Technology

- DC Current Sensing Technology

- AC VOLTAGE SENSING TECHNOLOGY

- AC VOLTAGE SENSING TECHNOLOGY

- DC VOLTAGE SENSING TECHNOLOGY

- Rogowski coil Technology

AC Current Sensing Technology

It improves both intrinsic errors in low current and errors occurred by external vibration and shock with strong durability and minimum tolerance on cutting cross section of core. Main applications are sub-metering, power meter, PLC(Programmable Logic Controller), energy automation and etc.

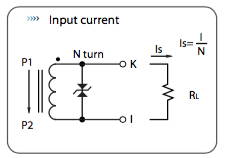

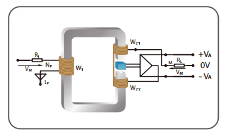

Measuring Principle

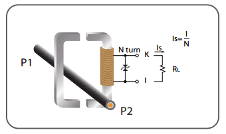

The core placed around the current bus is provided with a secondary winding(N turn), in which electromagnetic induction caused by AC electricity to be detected (I) induces secondary current (I/N).

The core material of J&D AC CT is saturated by the over current owing to the conductor, the linearity of secondary output current will be distorted and or the error of phase angle will be caused.

DC Current Sensing Technology

J&D DC CT provides non-contact detection of DC current.

The DC CT has two types of split-core & solid-core design with various utility, high reliability & cost-effective solution for precise current measurements. The rated current range is 5A to 30,000ADC and secondary output value is 4V/5V/10V/333mVDC & 4-20mA, Instantaneous DC current.

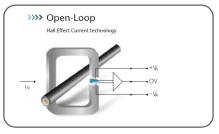

Measuring Principle of Open-Loop Technology

Open-Loop Hall effect technology creates magnetic flux from the input primary current and its magnetic flux couples a proportional low voltage, which amplify before being output.

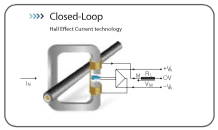

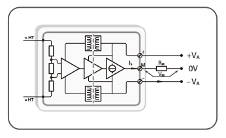

Measuring Principle of Closed-Loop Technology

The secondary current is generated by transferring the proportional voltage of the a hall sensor originated by the magnetic flux from the primary current. The feedback of the compensating current via the secondary winding closes the loop, where by this current is an exact representation of the primary current.

AC Voltage Sensing Technology

The J&D ACVT of compact voltage transformers are designed for applications where AC voltage signals must be transformed accurately into a lower AC voltage signal for micro-processor based circuits.

The ACVT of toroidal core, PCB voltage transformers are designed specifically for integrating products which require exceptionally accurate primary signal transformation when exposed to harsh environmental operating conditions.

ACVT model is designed and manufactured to meet the specific working conditions of the client’s specific application.

AC VOLTAGE SENSING TECHNOLOGY

J&D DCVT offers a comprehensive range of accurate, reliable and galvanically isolated devices to measure DC voltage from 10V to 1500V across a range of technologies.

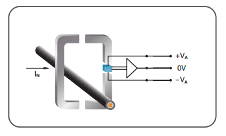

Measuring Principle of Closed-Loop Technology

When a primary voltage(electrical potential) is applied to a primary wire, current flows through the wire and generates an electrostatic field.

By mounting a Hall Sensor device within this electrostatic field, current is then induced into the sensor material of the device.

Measuring Principle of Isolation Amplifier Technology

Our Isolation Amplifier Technology Voltage Sensors – iSaST EVS Series begins with an internal resistor network. This network measures DC voltage by directly contacting both the Positive High Voltage(+HT) and the Negative High Voltage(-HT).

This voltage signal is transmitted to the secondary side of the sensor through an insulated transformer that isolates the Primary High Voltage from the Secondary Low Voltage. The resulting signal is then converted through an amplifier into either a current or a Voltage signal. Therefore, the circuit converts a primary voltage into a secondary current or voltage that is proportional to the input.

DC VOLTAGE SENSING TECHNOLOGY

J&D AC RCT provides non-contact detection of AC current. The AC RCT is clamp type of air-core design with various utility, high reliability & Cost-effective solution for precise current measurements.

The rated current range is 100 to 50000AAC and secondary output value is 0-5/10V or 4-20mADC and 1A/5A/333mVAC/Instantaneous AC voltage.

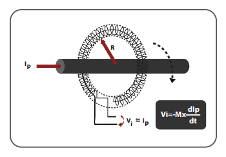

Rogowski coil is designed as open type and flexible sensor which can be installed to conductor easily. There are two terminals on end of coils and it is designed lead-wire spiral coil from one end to other end which is returned through center of coil. To provide optimizing transmission, length will be chosen by rated current measuring range. Primary current induced proportional voltage from output of coil. This technology supplies very high sensing on primary current changing value.

Electronic integrated circuit need to be changed from voltage signal to output signal which is proportional versus input current. Rogowski coil is possible to accurate mechanism and linearity sensing by additional electronic component and integrator circuit.

Rogowski coil feature

Rogowski coil has better frequency reaction than normal current transformer due to low inductance and non-magnetic core. It also does not use saturation core, so it is very accurate on high primary current. These kind of sensors are better to apply specially on power measuring system which has high current of fast changing current. To measure high current, normal current transformer is usually big and heavy. In contrast, Rogowski coil is small and light, so it is simply installed as advantage.

Rogowski coil technology

The AC CT has two types of split-core & solid-core design with various utility, high reliability & Cost-effective solution for precise current measurements. The rated current range is 5 to 2400AAC and secondary output value is 0-5/10V or 4-20mADC & 0.1A/1A/5A/333mVAC/Instantaneous AC current.

ROGOWSKI COIL TECHNOLOGY

J&D AC JCP provides non-contact detection of AC current

The AC clamp on current probes are based on AC transformer principle with various utility, high reliability & Cost-effective solution for precise current measurements.

The rated current range is 5 to 1000AAC and secondary output values are 0-5/10V or 4-20mADC & 0.1A/1A/5A/333mVAC.

J&D JCP provides non-contact detection of DC or AC current

To supply great property against electric jamming, it needs equivalent winding. This kind of performance is up to Rogowski manufacturing process. Other main points are positioning conductor in loop and consider opening clip from external conductor’s sensitivity.

Clamping clip makes sure of high symmetry on both end of coils and accurate mechanism overall. New technology in this field, as special hardware and electric property, possibly makes better accuracy and strong tolerance on conductor’s position. Conductor’s positioning error is not good as ±3% at 50/60Hz generally, but on the other hand, new Rogowski coil has error lower than ±0.5%.