Power Supply

Why Current Transducers are required for Power Supply

Stability and Sustainability are important keywords for equipment that needs power supply. For reliable and continuous operation of power supplies and drive systems, solutions for monitoring and controlling power quality are required. The role of the Current Transducers is one of the important ways the solution can be successfully realized, as the above factors are dictated by how accurate and reliable the CT is delivering the signal. This makes the equipment operate efficiently.

1. Stability

Many equipment, such as automation systems in industrial complex production plants, are sensitive to unexpected voltage fluctuations and power supply declines such as overcurrent, instantaneous voltage drop, and instantaneous peak. When power sourcing in the Generating system itself, errors occur, and it can be transferred to the distributed system as it is. This has dangerous factors that can lead to plant closures and loss of production. J&D Current Transducers can secure the reliability of the supply power by detecting these abnormal signals in real time through accurate and appropriate output verification.

2. Continuity

Devices that prepare for hazardous situations (e.g., hospital equipment) may pose risks if they do not receive continuous power. To prevent such risks, it is important to continuously check the power quality. Power quality needs to be continuously measured and analyzed so that unexpected hazards can be detected early.

J&D Current Transducers detect these degraded signals and increase the reliability of the supplied power. In addition, the JAGUAR IoT solution allows you to check power quality in real time.

Applications

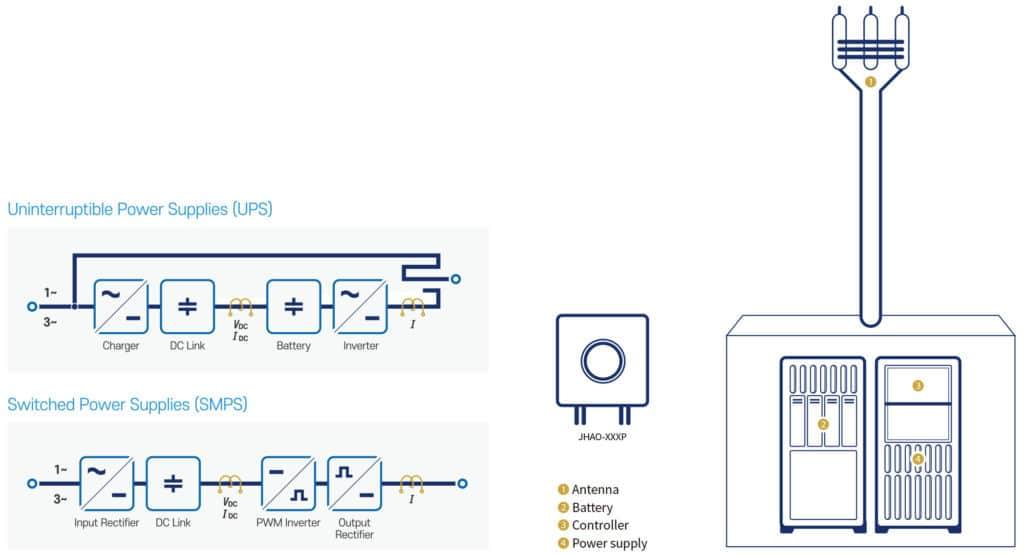

– UPS: Uninterruptible Power Supplies

– SMPS: Switched Mode Power Supplies

– Telecom Power Supplies

– Airport Lighting Power Supplies

– Lighting Power Controllers

– Battery Chargers